Introduction to Peanut Butter Production Process

Peanut butter is a globally beloved food product, favored for its rich nutty flavor and high nutritional value. Producing a smooth and creamy peanut butter requires specialized peanut butter machines that strictly control the production process. From cleaning and roasting to grinding and packaging, each step plays a vital role in ensuring the final product meets quality standards.

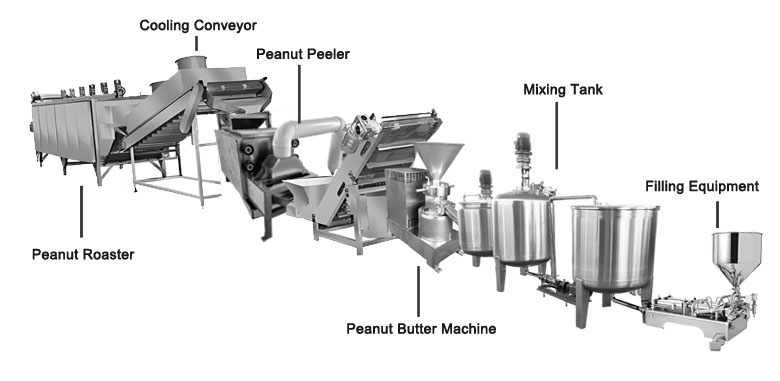

Peanut butter production process steps

1.Selecting and cleaning raw peanuts

The peanut butter manufacturing process begins with the procurement of quality peanuts. Raw peanuts are inspected to remove damaged or discolored nuts. They are then thoroughly cleaned using a specific-gravity stoner and vibrating screen to remove dirt, stones and other impurities. This ensures that only the best peanuts make it to the next stage.

2.Roasting for enhanced flavor and aroma

Roasting is a critical step in developing the unique flavor of peanut butter. Cleaned peanuts are roasted in large industrial ovens or rotating drums at 300°F to 350°F (150°C to 175°C). This process enhances the flavor of the nuts, removes excess moisture, and gives the peanuts a slight crunch.

3.Cooling and Red Skin Removal

After roasting, peanuts are cooled to room temperature to stabilize their texture. The peanuts are then run through a peanut peeling machine to remove the thin red skin. This step is critical to achieving a smooth, creamy consistency in the final product.

4.Optical and electronic sorting ensures premium quality

To ensure consistency, peeled peanuts undergo optical-electronic color sorting. State-of-the-art peanut butter machines use high-resolution cameras and artificial intelligence technology to detect and remove any residual impurities or discolored nuts. Some machines also include manual inspection for additional quality control.

5.Crushing and preliminary grinding

Selected peanuts are pulverized into a coarse pulp using an industrial grinder. This primary grinding stage breaks the nuts into smaller particles in preparation for further refinement.

6.Mixing with other ingredients

Depending on the desired flavor, ingredients such as salt, sweetener (sugar or honey) and vegetable oil are added to the peanut paste. This step ensures a balanced flavor and smooth texture.

7.Fine grinding for ultra-smooth texture

The mixture is then passed through a high-performance peanut butter machine for fine grinding. This stage refines the paste to a velvety smooth consistency, eliminating any graininess. Some producers use a combination peanut butter machine for an even finer texture.

8.Homogenization and cooling

After fine grinding, the peanut butter is stirred to evenly distribute the oils and prevent separation. It is then cooled to stabilize the mixture and extend shelf life.

9.Safe Vacuum Sterilization

To ensure microbiological safety, some manufacturers use vacuum concentration sterilization to remove oxygen and eliminate potential contaminants without compromising flavor.

10.Automatic Packaging for Freshness

The final product is transferred to an automatic filling machine, which precisely fills cans, bottles or pouches. Sealing and labeling is done quickly to maintain freshness prior to distribution.

Nutritional Value of Peanut Butter

Peanut butter is a protein-rich food containing 25-36% protein and up to 40% healthy fats. The unsaturated fatty acids in it can lower bad cholesterol levels and contribute to heart health. In addition, peanut butter provides essential vitamins (B3, E) and minerals (magnesium, potassium), making it a nutritious choice for young and old alike.

Improve Peanut Butter Production with Advanced Machinery

If you’re looking to start or expand your peanut butter production business, it’s crucial to invest in efficient peanut butter machines. Our team of experts can provide customized production solutions ranging from small grinders to full industrial production lines. Contact us today to learn how we can optimize your peanut butter processing!