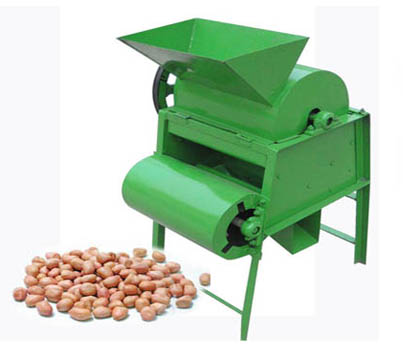

Peanut Shelling Machine

The Peanut Shelling Machine is a highly efficient device designed to remove peanut shells while keeping the kernels intact. Its high-speed rotating body is capable of removing the shells with a shelling rate of ≥95% and a breaking rate of ≤5%, making it an ideal choice for food or oil mill raw material. The machine's compact structure and easy operation make it a reliable performer, ensuring that the kernels are almost entirely undamaged during the process. Additionally, the peanut shell can be repurposed to make wood pellets or charcoal briquettes for fuel. We offer a range of models to choose from, including smaller ones for home use, all with excellent performance. Trust our Peanut Shelling Machine to deliver quality results with every use.

BK-200 small peanut shelling machine

Capacity: 200KG/H

Powder:2.2KW

Voltage:220V or 380V

Packing:630*600*930mm

Weight: about 40kg

BK-200 small peanut shelling machine contains 3 parts, the destoner for peanuts, conveyor and the groundnut sheller. Its main advantages include simple structure, easy operation, small and easy to move, high efficiency and low breakage, long service life, low price.

BK-400 peanut seed sheller for sale

Model: BK-400;

Motor power: 2.2 kw;

Voltage: 220v;

Capacity: 400-600kg/h;

Dimension: 1350*600*800mm;

BK-400 groundnut sheller machine is specially designed for shelling peanuts, the shell rotary roll is made of high quality timber. This machine is nice in appearance, small and practical, with simple structure, easy to operate, low power consumption, low noise and so on.

BK-700 Peanut Shelling Machine

Model: BK-700

Voltage: 380V

Power: 3kw

Capacity: 500-700kg/h

Dimension: 1450*800*1850mm

BK-700 machine produced by our company has many features such as low peanut breakage rate, separating clean, and little impurity. This kind of machine include rasp bar, stake, intaglio, fan, gravity separator and second bucket etc.

BK-3500 big capacity peanut shelling machine

Model: BK-3500

Crushing rate <=4%

Power: 2*7.5kw

Capacity: 3500kg/h

Dimension: 1450*800*1850mm

BK-3500 type peanut shelling and cleaning machine is a new generation of multifunctional speed-regulating peanut shelling machine developed by our company for our customers. The peanut kernels processed by the peanut sheller machine are in good quality, with bright color and less breakage.

BK-3500B peanut shelling and cleaning machine

Model: BK-3500B

Voltage: 380V

Capacity: 3500kg/h

The peanut shelling unit consists of two parts: peanut cleaning machine and peanut shelling machine. Peanut cleaning machines can remove a lot of clods, stones, peanut leaves, and dust from peanut raw materials.

Automatic Peanut Shelling Machine Made in China

Peanut shelling machines are essential tools for the peanut industry. They are designed to remove the outer shell or hull from the peanut kernel without causing damage to the kernel itself. This process is critical because it makes the kernel more palatable, easier to store, and more suitable for processing into various food products.

One of the key advantages of peanut shelling machines is their ability to handle large volumes of peanuts quickly. This is especially important for commercial peanut processing plants, where time is of the essence. With the help of peanut shelling machines, these plants can process vast quantities of peanuts in a fraction of the time it would take to do so manually.

In conclusion, peanut shelling machines play a critical role in the peanut industry. They are essential tools for removing the outer shell from peanut kernels quickly and efficiently. With their ability to handle large volumes of peanuts and reduce waste, they are an invaluable asset for commercial peanut processing plants.

Working Principle of peanut sheller

Peanut fruit artificial feeding, first fell on the the crude Wen gate, fall through grid text plate rotational rubbing force between fixed the trash rack concave plate, peanut shells peel separation peanut shell,through duct the most peanut shell blowing hit by the wind machine, with peanuts and peanut small part has not been stripped fruit falling into the proportion of the sorting screen, after re-screening, peanuts line separating screen surface by material mouth into the sacks, but have not yet stripped peanuts (small fruit) from the screen surface downstream, after the material crossing into the hoist, and then from the elevator into the fine lines gate secondary sheller proportion of branches, and then after screening election, you can reach all the peel.